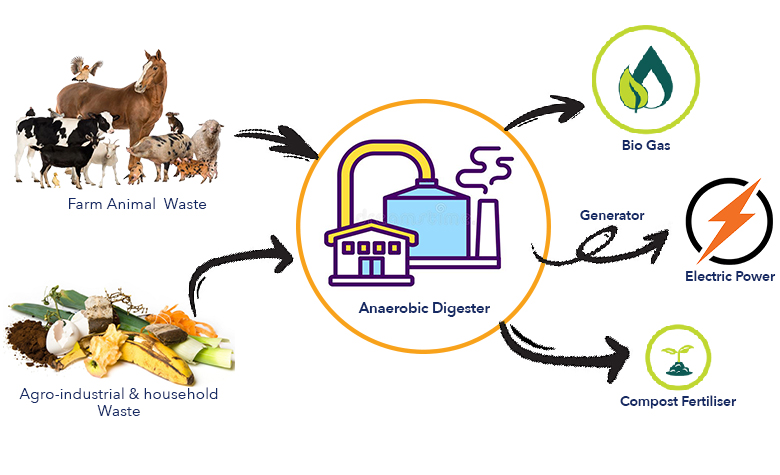

Anaerobic Digestion

Biogas is produced when organic matter is broken down through Anaerobic Digestion in an airtight vessel. AD draws on eco-friendly and sustainable concepts to produce Biogas through the breakdown of organic matter, meaning less waste and more usable products for a variety of applications. Biogas is made up of mostly Methane and Carbon Dioxide; through gas cleaning and compression it can be used as a replacement for LPG Gas.

As fossil energy prices and supplies vacillate, and the need to reduce greenhouse gas emissions, our nation looks toward renewable energy generation and energy independence. For this reason, capturing energy from food waste and agricultural byproducts is becoming more important. Post-consumer food scraps (biomass) can have up to three times as much energy potential as biosolids.

Products and By-products of Anaerobic Digestion

Traditional ‘wet’ AD systems rely on high energy and water input to turn wastes into a soup that can be pumped around the system to extract energy, after which the digested waste is discharged to land.

The innovative batch system at Naivasha is a high solids system particularly suited to the digestion of high cellulose agricultural waste such as flowers. The system retains the solid waste in cages inside the digestion vessels and circulates only a dilute bacterial inoculum that looks rather like tea. This approach dramatically reduces the energy required to operate the system and the liquid inoculum or ‘tea’ can be retained and used again and again when the digested solids are removed and replaced with fresh waste.

This approach cuts both the capital and operational cost of the system and can digest high solid wastes that are not normally suited to traditional AD systems.

Benefits of a Bio Digester

- Recovery of energy from waste

- Reduction in energy costs

- Reduced greenhouse gas emissions

- Reduced waste volume

- Production of natural fertilizer

Biogas biofuel – Replacement for Natural Gas

Biogas consists mainly of methane (60% to 80%) and carbon dioxide (20% to 40%) with some other gases, such as hydrogen sulfide, ammonia, and water vapour, in trace amounts. Biogas is highly flammable and is produced through the anaerobic decomposition of organic materials from plants and animals. It can be used for heating cooking and power generation.

Electricity Generation from Biogas

The energy content of the gas depends on its methane content. High methane content is therefore desirable. Some carbon dioxide and water vapor content is unavoidable, but sulphur content must be minimized – particularly for use in engines. The biogas yield of a plant depends not only on the type of feedstock, but also on the plant design, fermentation temperature and retention time.

Biogas is used as fuel for combustion engines, which convert it to mechanical energy, powering an electric generator to produce electricity.

For use in engines, the gas must fulfil certain requirements:

- The methane content should be high as this is the main combustible part of the gas;

- The water vapour and CO2 content should be as low as possible, mainly because they lead to a low calorific value of the gas;

- The sulphur content, mainly in form of H2S, must be low, as it is converted to corrosion-causing acids by condensation and combustion.

Digestate- separation

In this system we have meshed cages that hold the solids in place during the digestion period. Separation of the liquid digestate helps reduce parasitic load and the liquid digestate is retained between batches for use as inoculum in the next cycle.

Digestate as Natural Fertilizer

During the anaerobic digestion process, nutrients contained in the feedstock are mineralized. Mineralized nutrients are easily used by a crop. Digestate solids are high in fiber, consisting mainly of fibrous undigested organic material and contain higher concentrations of plant-available nitrogen and phosphorus. This solid digestate can then be used as bio-fertilizer to enhance crop growth or fed to worms for further digestion.

Other possible value added products using digestate solids

Digestate solids can also be used as substrate in compost, providing sources of carbon and nutrients. Solids can be dried and pelletized as fertilizer or fuel.