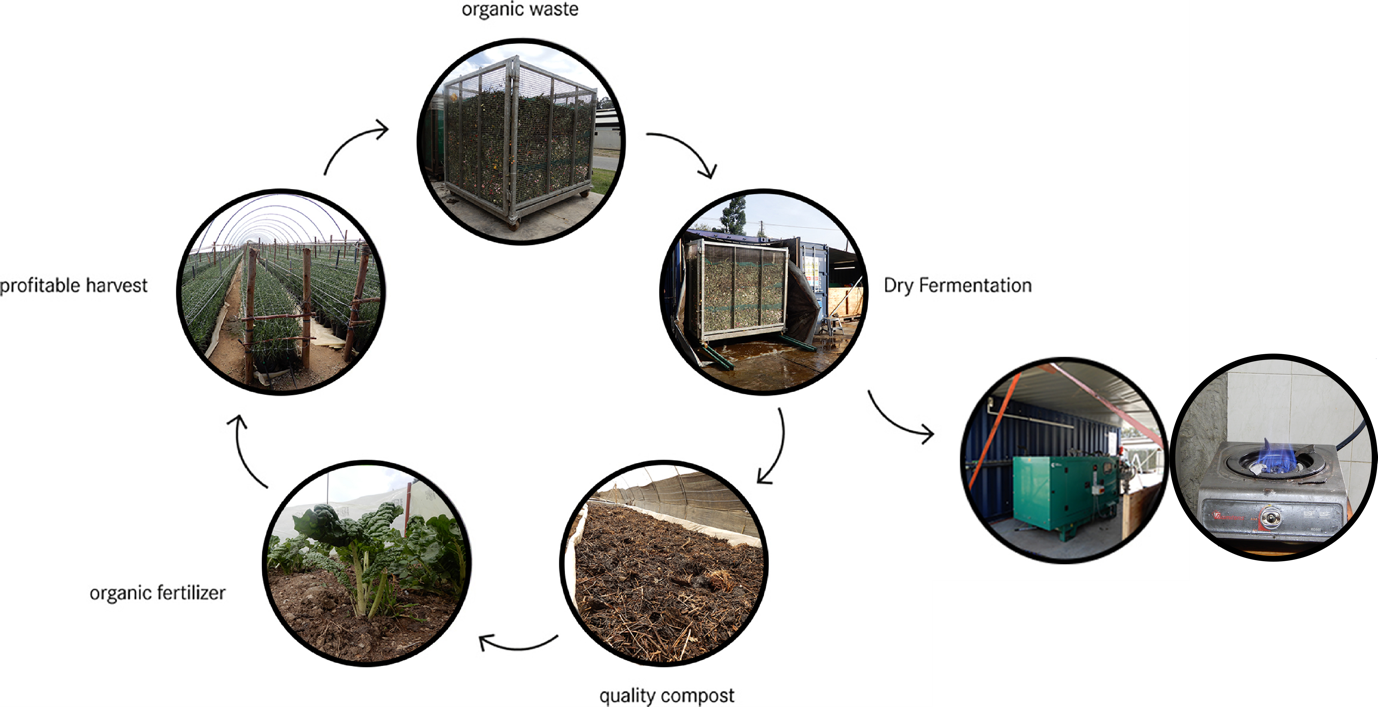

Anaerobic digestion (AD) is a microbiological process whereby organic matter is decomposed in the absence of oxygen. Using an engineered approach and controlled design, the AD process is applied to process organic biodegradable matter in reactor tanks, to produce biogas.

Common bio-waste include;

Municipal

- Organic Fraction of municipal solid waste (“biowaste”)

- Human Extra

Agriculture

- Manure

- Energy Crops

- Algal Biomass

Industry

- Agro-Industrial Waste

- Slaughterhouse Waste

- Food Processing Waste

- Biochemical Waste

Benefits of biogas technologies

Anaerobic digestion of organic waste provides many benefits. This includes the generation of renewable energy, a reduction of greenhouse gases, a reduced dependency on fossil fuels, job creation, and closing of the nutrient cycle. It transforms organic waste material into valuable resources while at the same time reducing solid waste volumes. Biogas not only improves the energy balance of a country but also contributes to environmental protection by reducing deforestation and by reducing pollution from waste and use of fossil fuels

Classification of AD technologies

Numerous AD technologies for the treatment of bio-waste have been developed worldwide. Digesters range in complexity from simple cylindrical cans with no moving parts to fully automated industrial facilities. There are three main types of conventional liquid digesters:

Fixed Dome

Floating Drum

Tubular Digester

All of these operate in a continuous cycle. The system at Bohemian Flower Farm is different. It is a derivation of the garage-type digester.

Garage-type digester

Our Garage-type digester system required us to convert shipping containers to be our reactors. Qube Renewables started putting together this kit back in the UK which included Lab Equipment, Control system, Container conversion materials and Gas usage system. To make a Biogas digester, you need an airtight vessel where digestion will take place and a gas store.

Gas store took the form of a flexible 20M3 bladder. For this system to work it also requires the installation of components such as the automatic control panel, pipelines, heating system, gas cleaning system and a generator.

System Operation

This is a batch system capable of digesting high solid wastes.

We get flower waste from bohemian flower farm. The bio-waste is then loaded into trollies which can carry upto 1.5 tonnes of bio-mass load. The container digester fits a max of 3 trollies which can stay upto 60 days while producing biogas. The Inoculum is then pumped into an empty reactor to be used for the next cycle. Here, all system operations are controlled from the monitoring panel.

After venting the container digester, cages are pulled out emptied and the nitrogen rich solid digestate is taken to the compost, worm farm or used as natural fertilizer on the farm.